puget sound energy

If you are like most environmentally conscious people, solar power has been on your radar for a very long time. You may have even developed a habit of waiting for the technology to become more solid, mainstream, and affordable; waiting for the first wave of users to help work out the kinks and develop a perfected product. Until about three weeks ago when I began my research on the Solar Agent position at Power Trip Energy, I thought we were still in waiting mode.

As my training on grid-tied PV has progressed at Power Trip Energy, it has dawned on me that the “early adopter” phase for residential solar power may have already passed. My family has always been the sort who are first on our block to embrace such things as microwave ovens and home computers, cell phones and Netflix. Thankfully, we can keep our technological early adopter self-image intact. Despite the fact that residential solar power has become so mainstream that we can now share our democratized power production with the utility grid and be paid for it at 100% the utility’s selling rate, we can still be the first on our block to invest in a flashy and affordable new solar array!

Your wait is truly over. Residential grid-tied PV solar technology has become more than a logical investment in the future livability of our planet; it has also become fiscally practical, paying for itself over time, increasing our property values, and significantly reducing our power bills immediately. Power Trip Energy was brave enough to show up early and paddle out to the big wave. Now they, I mean WE, are ready to join you in riding that wave back to shore.

What strikes me most about the super awesome community members at Power Trip Energy is their integrity and commitment to our habitat. From the electric personal cars and bicycles in our parking lot to partnering with companies that insist on producing solar modules sustainably, Power Trip Energy is making a real impact on our future for generations to come. I am honored to join them in this powerful movement and eager to share the electricity with you!

Photo taken on Puget Sound Express‘s Glacier Spirit whale watch touring vessel. Hudson Point Marina is in the background. Heather Flanagan is the newest member of the Power Trip Energy team. Originally from Portland, Oregon, she now calls Port Townsend her home. Heather lives in Uptown with her two boys, Logan and Blake.

by Andy Cochrane | Aug 26, 2016

Mansfield Residence – 7.85 KW SunPower Array on Fronius 10 KW Inverter – Port Townsend – December 2015

SunPower last year verified 25.2% efficiency in a manufactured silicon-based PV cell. This year, they have integrated that cell into a manufactured PV module which attains 24.1% efficiency. When making efficiency comparisons, the cell-level efficiency is less relevant as in order for us to utilize that power, we need the cells built into a module, which will necessarily be slightly less efficient due to the space between cells, and the small area occupied by the frame.

When we are designing a system for a home’s roof, we usually need to make as much power as we can on the available roof space in order generate the largest percentage of the home’s annual energy. So using the most efficient modules available is important to us. While these SunPower modules are not the least expensive on the market, when we can put up an array with higher power rating in the same space as an average array, we can recognize relatively lower $/watt installation costs on all the other aspects of the system.

We are now commonly utilizing SunPower X-21 345 watt modules, which are 21.5% efficient at the module level. Their high efficiency, finish quality, and industry-leading warranty make SunPower an excellent choice for almost all of our clients. For example on the installation from last winter pictured above, we used the SunPower 327 watt modules to get 7.85 KW in the available un-shaded space. If we had used an average module, running ~290 watts in this size right now, that would be a 6.96 KW array in the same space, 12% less power installed for the same amount of work.

https://us.sunpower.com/blog/2016/06/26/sunpower-solar-module-verified-241-percent-efficient/

by Andy Cochrane | Jul 7, 2016

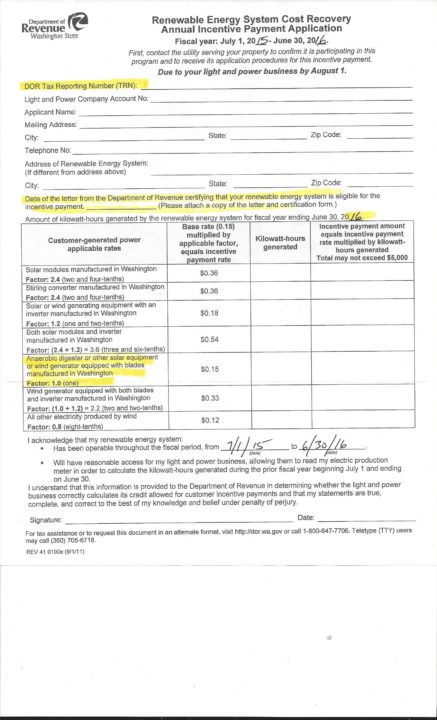

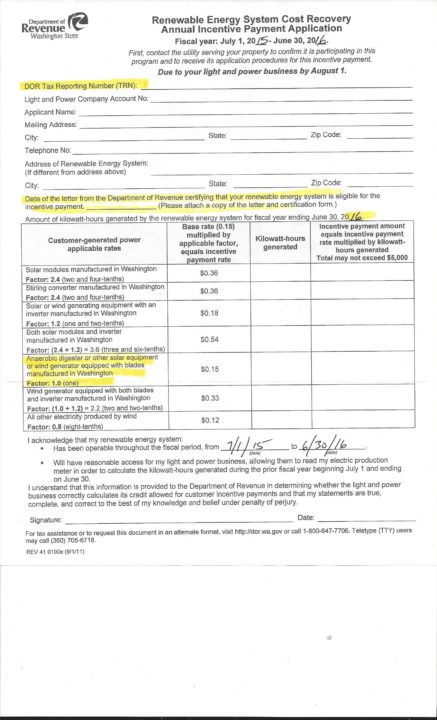

The annual Washington solar production incentive payments are based on the fiscal year from July 1 – June 30, so everybody with a grid-tied pv system is about to read their meters for the 2015/2016 year.

You will get a letter containing this form below. If you are a PSE customer, the form will be filled out for you. We are not certain what the Jefferson and Clallam PUD’s are planning this year. We have highlighted some of the important fields.

The main thing you want to bear in mind is to go read your production meter on June 30. Even if you are in PSE territory and they are going to read your meter and provide the information for you, we recommend reading your meter yourself at least annually. Then you will want to compare that figure with last year’s June 30 reading in order to get your annual production figure for this year. You will also be able to copy your DOR Tax Reporting Number from the top of last year’s form.

Unless you are among the minority of our clients who have the Made in Washington PV modules from Silicon Energy or Itek, you will use the field highlighted to report your total kilowatt-hours for the year. Although the base rate is stated as $0.15, all utilities in which we operate are or will be pro-rating this base rate due to the fact that the applications are now exceeding the available incentive pool, of 0.5% of taxable utility revenues.

by Andy Cochrane | Jun 20, 2016

There are several trends in the solar industry that are benefitting us locally, and driving our growth. We are currently installing over 60 KW per month, having installed 180 KW in Q4 of last year, and Q1 of 2016. That means in each quarter, we are installing as much solar as we did the first five years of business from 2003 through 2007.

We continue to see prices on pv modules slowly decrease, mostly as a result of global manufacturing capacity increases and efficiency gains. SunPower specifically has seen recent gains at its fourth “Fab” and is now approaching producing 1500 MW of pv per year.

So as a result of this increased manufacturing capacity, SunPower has been able to give us a fairly significant price cut recently, in addition to adding a 360 watt version of their standard residential pv module. We have been installing mostly 327’s for the last year, though now the 345’s are very close in price per watt and will make up the bulk of our designs for the remainder of the year. In cases where we want to make the most power possible, we will give our clients the option of the 360 watt product.

The increased installation rate here at Power Trip Energy also creates an interesting dynamic in terms of our pricing. With more and larger projects being installed each month, without our overhead significantly increasing, we can lower our installation charges on each job. So the lower equipment costs are actually resulting in lower labor charges as well.

The extension of the federal tax credit has removed a major deadline we were facing at the end of 2016 so we can intelligently plan for manageable growth this year. The waning state incentives should be considered, since we have about four more good summers to capitalize on those annual production payments from the state.

We don’t know how long these market conditions will persist, but we do know there has never been a better time to install a grid-tied pv system in Washington.

6.21kw SunPower, Sequim 2015

by Andy Cochrane | Apr 20, 2016